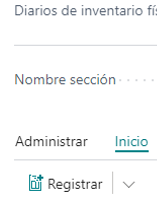

General Operations

In this section, we cover the basic operations to be carried out in the warehouse, which can be summarized in the following image:

Read Location

- Read Location: Used to check the contents of a specific warehouse location, displaying products with lot, serial numbers, palletized items, and items without tracking (those without serial or lot numbers).

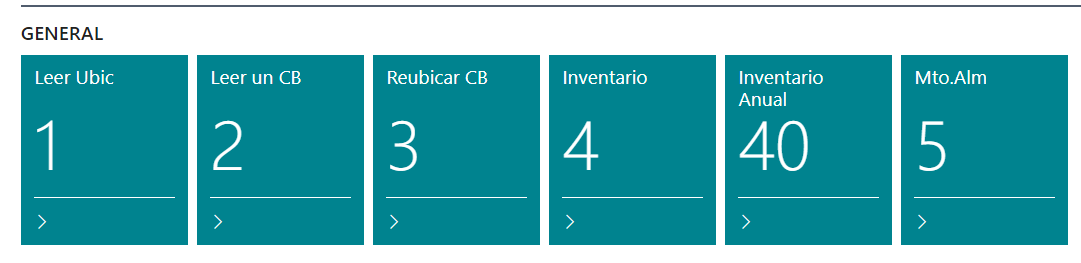

Upon entering the screen, you'll see:

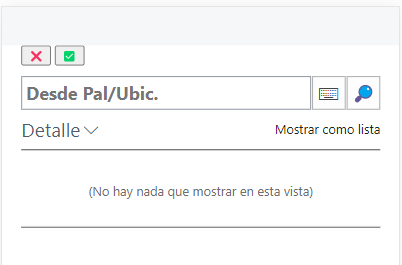

When reading a location or a pallet (view the content):

Interface aspects:

- Buttons to open a touch keyboard (integrated camera) and search from a list, in this case, locations:

Read Barcode

We can read a Product, Lot, Serial, Pallet, supplier code, etc., and the system adapts to the type of reading.

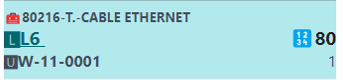

For example, scanning a QR code of a product (80216-T) will display the breakdown of where it's available and the quantity, for products with lot, serial numbers, pallets, or without tracking. In this example, we see both non-palletized:

and palletized items:

Reading a pallet's barcode shows its location and contents.

Relocate Barcode

- Relocate Barcode: Used to change the location within the same warehouse of a product QR or a pallet barcode (moving its entire content) to another location.

Permanent Inventory

- Inventory: In case of a stock discrepancy requiring immediate correction ("permanent inventory"), positive or negative adjustments can be made for a specific QR. If the product is palletized, it needs to be depalletized first.

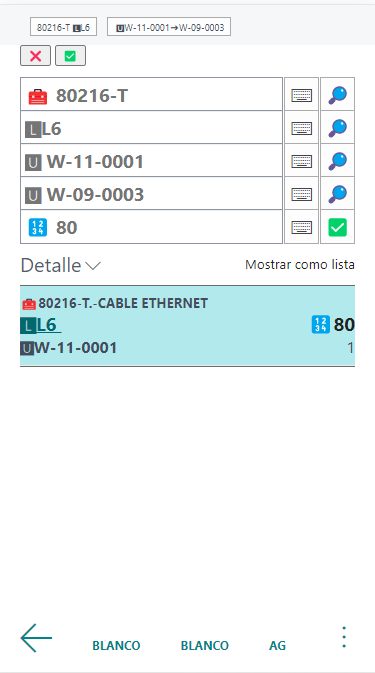

For instance, moving 80 units from one location to another:

To register the operation, always click on the ellipsis in the Quantity:

or use the top section with two actions respectively: Clear Filters and Register:

Periodic Inventory

- Annual Inventory: This inventory process is conducted before closing the fiscal year. It can be initiated as many times as needed, not necessarily just once a year as typically done.

The process involves:

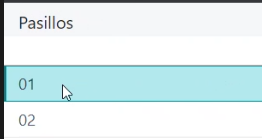

- First, you'll be asked to enter the aisle:

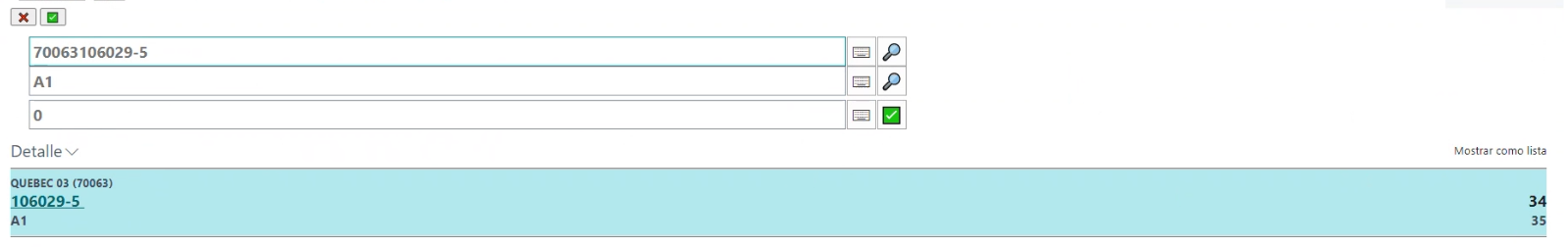

- Conducting the inventory of that aisle and adjusting quantities if necessary:

- Automatically creating a section for the aisle being inventoried:

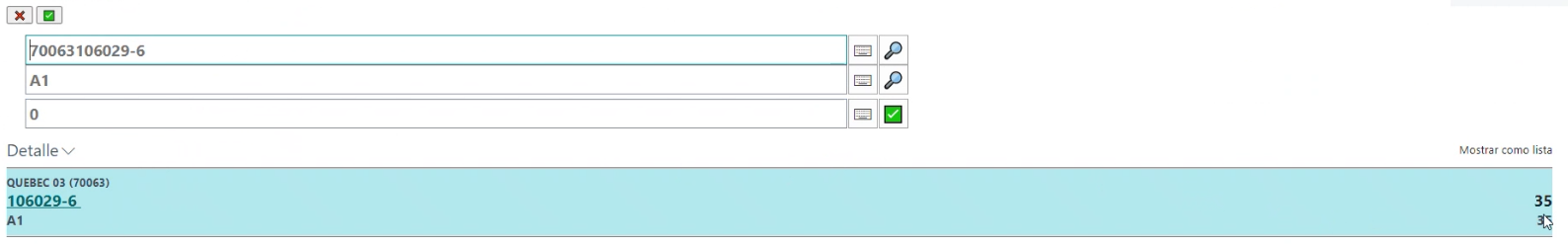

- All readings, whether they modify the quantity or not, are logged in the Inventory Journal. For instance, counting 35 units that are in stock:

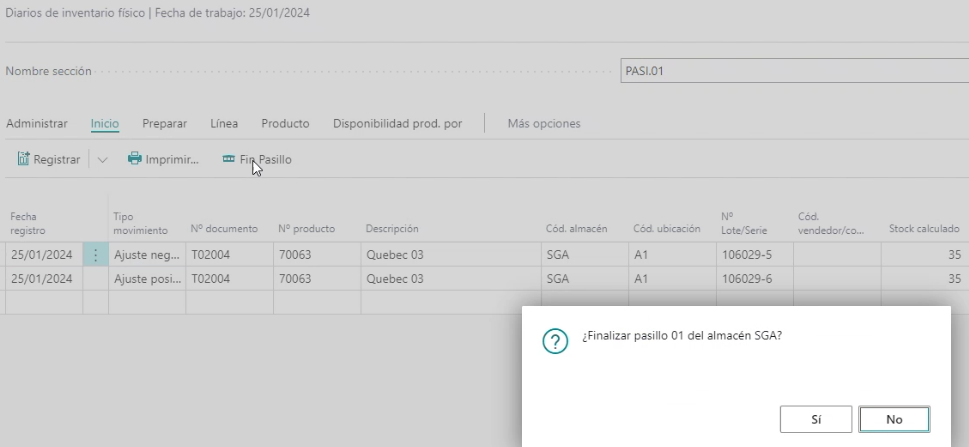

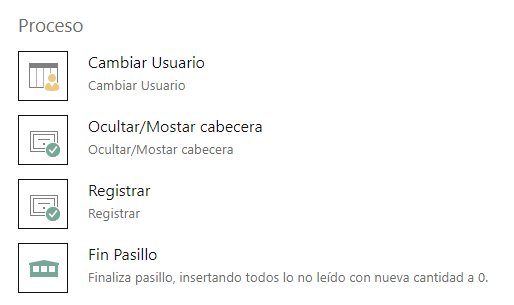

- Upon finishing the aisle, the "Finish Aisle" action is used (available in both PDA and desktop screens), which adds lines for the unread stocks to set them to zero:

From the PDA:

- Viewing the first two lines we read: the first adjusted by +1 and the second found as is, and the two lines that zero out the stock for items not found:

- The inventory journal's registration is manual and carried out by the responsible person from the Journal screen, not from the PDA: