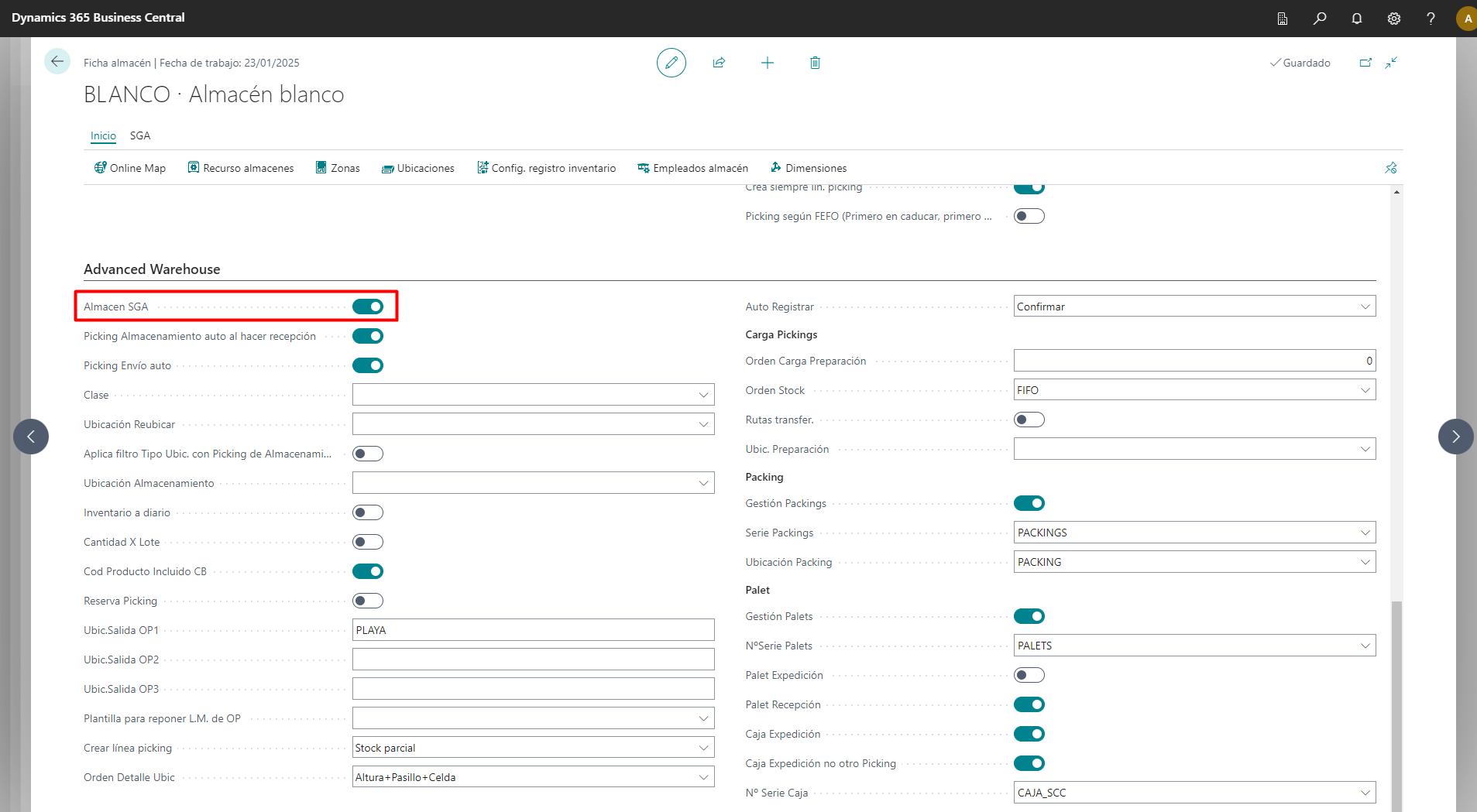

Warehouse Configuration

For each warehouse, the first step is to activate it as an iDynamics Advanced Warehouse:

Features

iDynamics Advanced Warehouse: Activate those that will be managed from the PDA.

Auto Storage Picking: When creating a reception, the storage will be automatically created transparently to the user to be read from the PDA.

Auto Dispatch Picking: When creating a shipment, the sales picking will be automatically created transparently to the user to be read from the PDA.

Class: Classifying effects of the warehouse.

Re-Location Location: Can be used in the client extension to provide specific functionality.

Type Location Filter Applies: If we want to consider these advanced warehouse filters when creating a relocation movement.

Storage Location: If filled, it will be taken as a default to search for lot traces in outbound pickings. If blank, it operates on the logic of the location type if it is an advanced warehouse.

Daily Inventory: Do not register inventory on every operation but dump it into a product reclassification journal for supervision and registration from the journal.

Lot Quantity: Double-unit picking system for variable lot quantities (e.g., pieces in textiles). It sets the default quantity that will later be redefined for each specific product. To specify this lot quantity for each specific product, refer to the product configuration.

Batch/Series Code included in CB: If the barcode, for example, a QR code, provides product and lot information and does not require a double scan. The reading screens will adapt to one or two fields.

If check:

Not check:

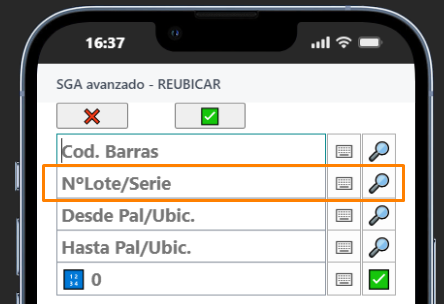

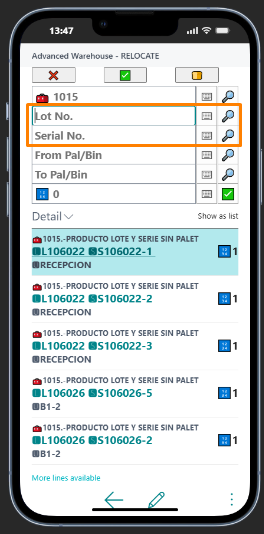

Separate Lot and Serial

Specifies whether lot and serial numbers should be entered in separate fields instead of a combined one on warehouse management pages used by warehouse employees.

Reservation in Picking: If stock reservation is made while picking to prevent allocation to another picking.

Generic Locations 1..3: 3 general locations for relocations from them. You can have as many as needed, but these three have their activity in the Role Center by default.

Template to replace OP's LM: Used to provide raw material for productions. Configure the rules in this template to search for the stock.

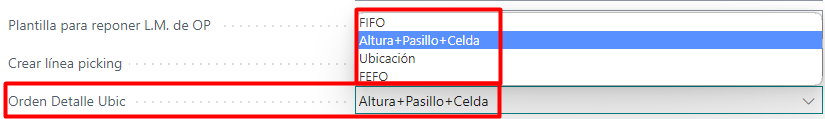

Create picking line: Allows three values:

- Create always even if no stock available.

- Only if there is enough stock to fully serve the line.

- If there is stock to serve in part even if it couldn’t serve completely.

Picking line order: The order in which the lines will appear in the picking, whether FIFO or by location for optimized routing.

Auto Register complete picking: Defines the behavior when completing a picking if:

- Do nothing.

- Ask for confirmation to register automatically.

- Automatically register without asking for confirmation.

Picking Load

Load Preparation Order: If we want this warehouse to be part of the loading, give it an order > 0. If multiple warehouses have order: 1,2,3... it will be the sequence of stock search. If not found in the first warehouse, it will search in the second...

Stock search order: Usually by FIFO to sell the oldest first, but in some scenarios, it might need to be by quantity (e.g., textiles) where it's important to find the quantity closest to what is requested.

Transfer routes in stock search: If it should look in other warehouses that have a transfer route between them to complete the order.

Preparation location: ...

Packings

Packing Management: If enabled, when registering a sales picking, the unregistered packing will be generated. If disabled, packing management is off, and each picking will be registered, creating the sales order directly. Packing Series: Serial number for packings. Packing location: When registering a picking and passing to an unregistered packing, the goods move to a specific location to know what is prepared and to block that stock.

Pallet Management

Pallet Management: If the warehouse uses pallets encoded with a barcode and can be located, moved, read for sales picking... Pallet Series: Serial number to create new pallets. Shipment pallet: If we want to palletize when preparing sales pickings for items scanned. Reception pallet: If, when receiving a purchase order, we can palletize the goods as we read them during the process.

Palletizing can always be done after stock entry, even if the checkbox is unchecked and palletization is not intended at the time of entry reading.

Dispatch Box: If we want to pack items while preparing sales pickings and have traceability of the box as a shipment item that could be sent, for instance, through EDI or any other treatment requiring box traceability. Expedition box not in another picking: If we want to verify that the box is not in any other picking to prevent labeling errors. Box Serial Number: Number used for creating new boxes.

Packing Number: Serial number used for packings per warehouse.

Preparation Loading Order: To calculate the loads of the warehouses.

Transfer Routes: If we want, in case of a lack of stock in the main warehouse, to look at secondary ones defined in the warehouse routes to fulfill that order.