Traceability and Movements

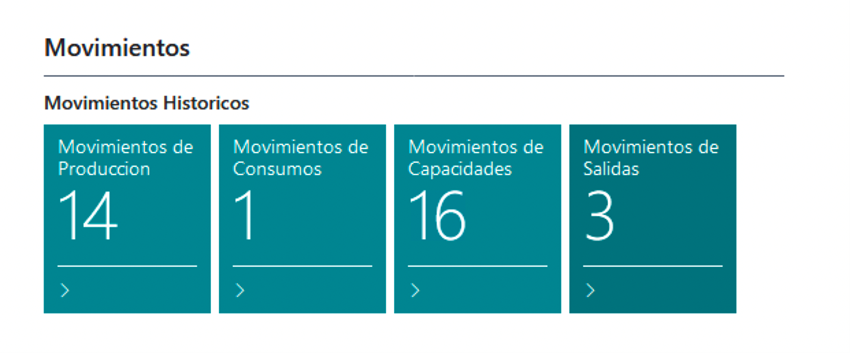

There are 4 activities to view historical movements:

Production Movements

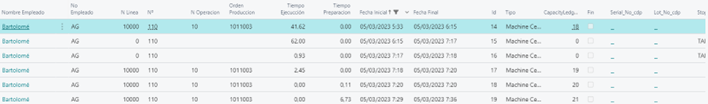

These movements show the times carried out by each person and whether they involved production output or not.

If there's a capacity movement associated with production, we can navigate and view it. The time can be modified if there were any errors.

Also included are the stop periods when the machine was stopped, for creating stop dashboards, without associated capacity movements.

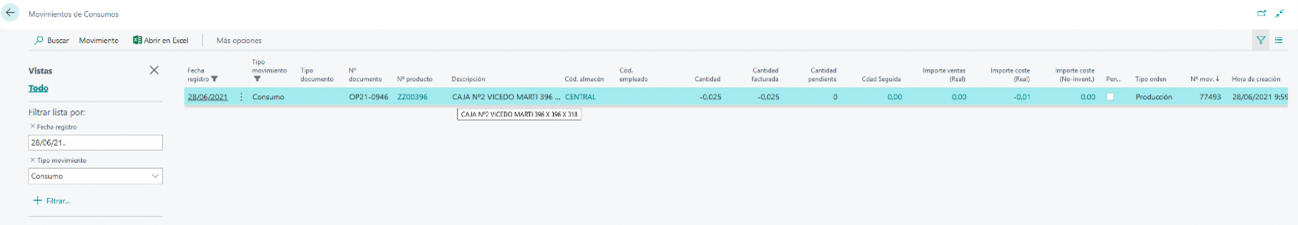

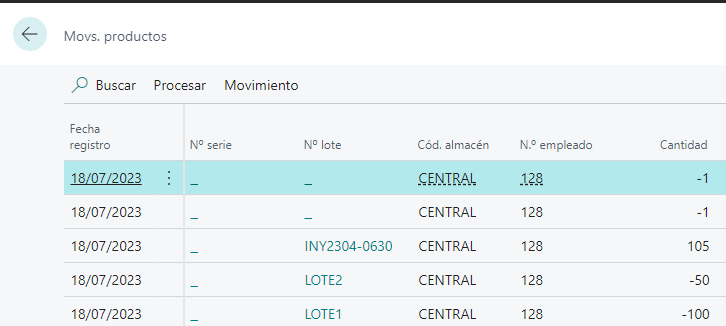

Consumption Movements

Here, only the example of manual consumption made in the Materials section will be displayed.

Capacity Movements

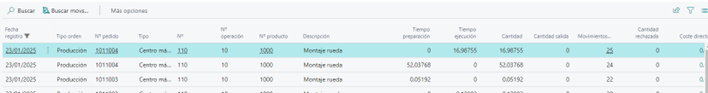

To reconcile all costs in Business Central, iDynamics Shopfloor separates movements with quantities from movements with times. In standard capacity movements, it only records time quantities but the start and end dates of each movement.

This achieves an exact cost and a more efficient time tracking per employee provided by the Production Movements table.

Production Output Movements

Product output movements are generated directly upon registering them, so there's no need to register any journal subsequently to get the stock, as it is always in real-time.

Operator

In iDynamics Shopfloor, we can always know which operator has performed a specific operation because the Employee field is added to the main tables of Business Central. For example:

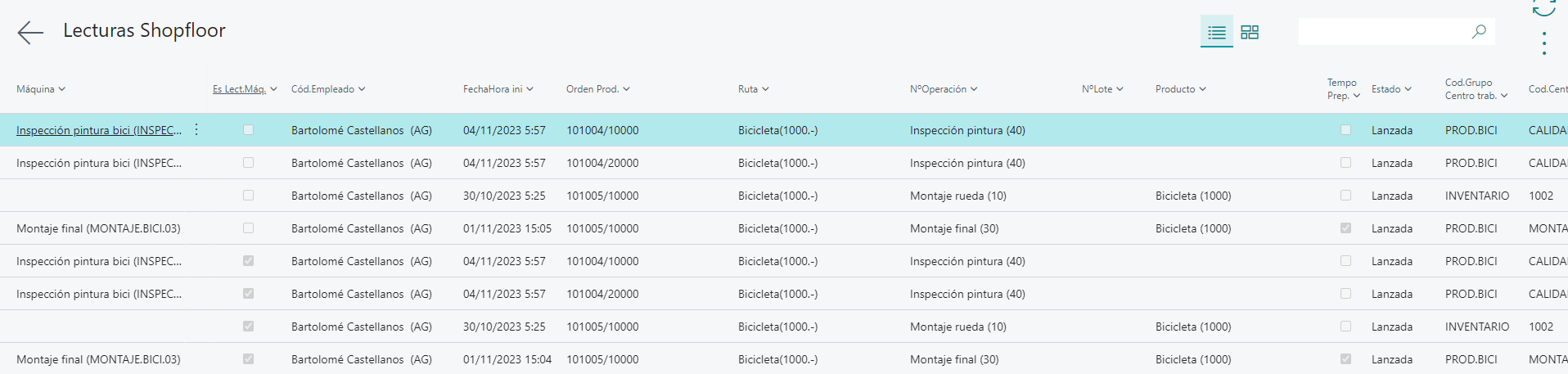

Current Machine Readings

From the following activity that we can find in the Role Center, we can see the status of the plant:

In this screen, we see the machines that are running, the operator, start date...

To generate a report or a dashboard on the plant's status, it can be obtained from this table. Machines not appearing mean they are stopped, while those that do inform us about the task, production, operator... currently performing it and also the date-time it started the current activity.