Warehouse documents

Overview

In locations where all the warehouse features of Business Central have been enabled (advanced warehouse) users will be able to handle the following documents from the mobile app: Shipments, Receipts, Picks, Put-aways and Movement tasks.

In warehouses where only the Bin Mandatory, Require Put-away and Required Pick options have been activated (basic warehouse), users will be able to handle Inventory Put-aways, Inventory Picks and Inventory Movements.

Sea un almacén básico o avanzado, todos los documentos anteriores son susceptibles de ser gestionados mediante la aplicación móvil de iDynamics Warehouse. La manera de trabajar en todos ellos, cuando van a ser gestionados desde la aplicación móvil, es similar:

- Create the document in Business Central.

- Assign the document to a warehouse employee, or let users lock them from the mobile app.

- The warehouse employee will handle the document, taking/placing items as needed.

- The employee will send all lines to the server and confirm that they have finished with the document.

- If the employee can post documents, this will be automatically posted. If not, it will be marked with a Processed mark, until someone posts the document in Business Central.

If you have not already done so, please refer to the basic warehouse first steps guide or the advanced warehouse first steps guide, as appropriate for your case. These describe, step-by-step, how to handle a purchase order using iDynamics Warehouse, including the various warehouse documents associated with receiving the order.

iDynamics Warehouse barely changes the standard functionality of Business Central. All data sent by each user is stored in a table called Read Buffer. At the time of posting each document the application will query that table and, if data has been sent from the mobile application, the quantities (and tracking numbers, if applicable) will be applied to the document lines, before following the standard Business Central posting process.

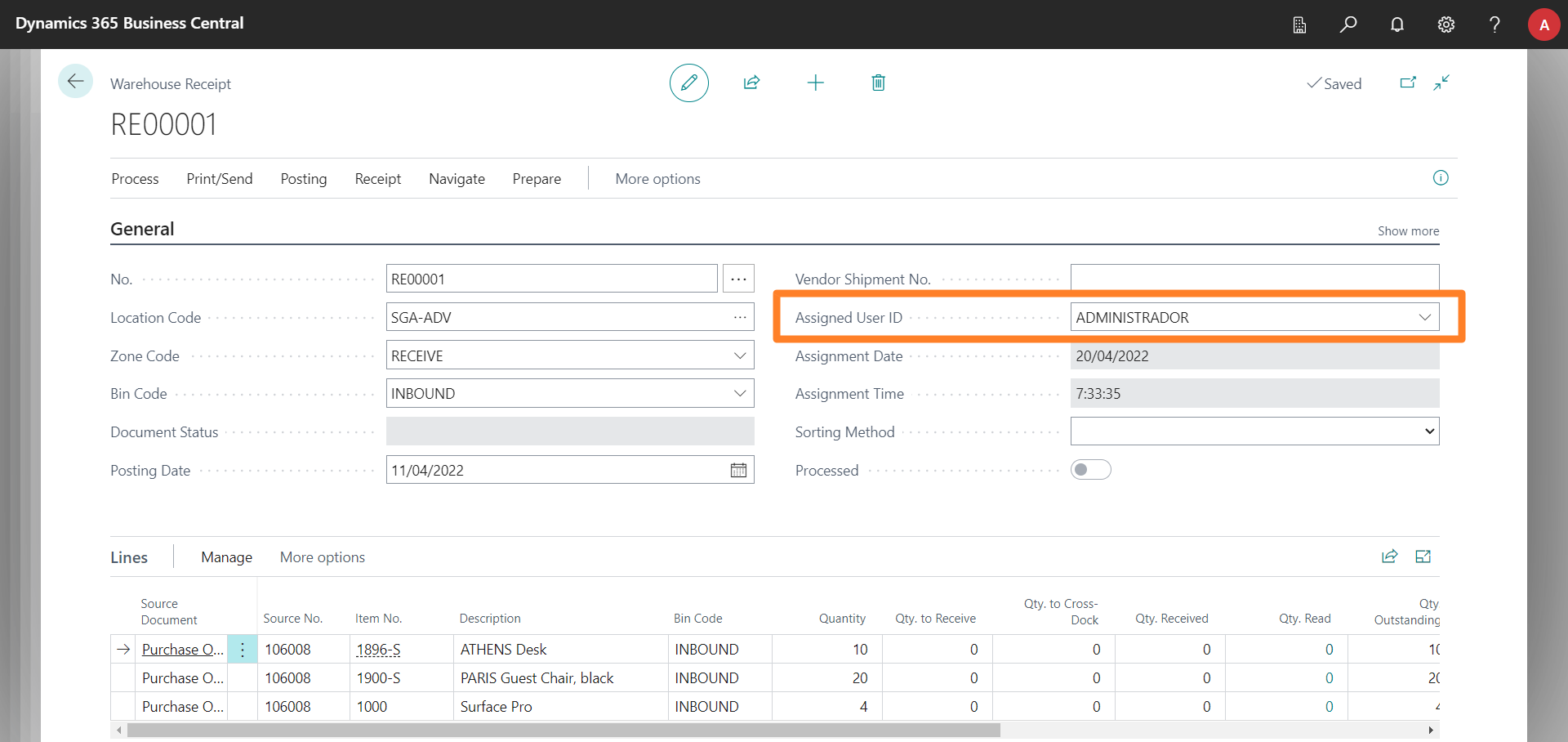

Employee Assignment

iDynamics Warehouse uses the standard field Assigned User ID available in all warehouse documents. If a warehouse employee is assigned in this field from Business Central, the corresponding user in the mobile application will see the document as assigned and in their task list.

De la misma manera, las acciones de bloquear o desbloquear documentos de la aplicación móvil asignarán o vaciarán el valor de este campo.

En cada momento sólo puede haber un operario trabajando con un documento de almacén. Si un documento está asignado a un empleado, el resto podrán consultar su información, pero no podrán actualizar sus datos.

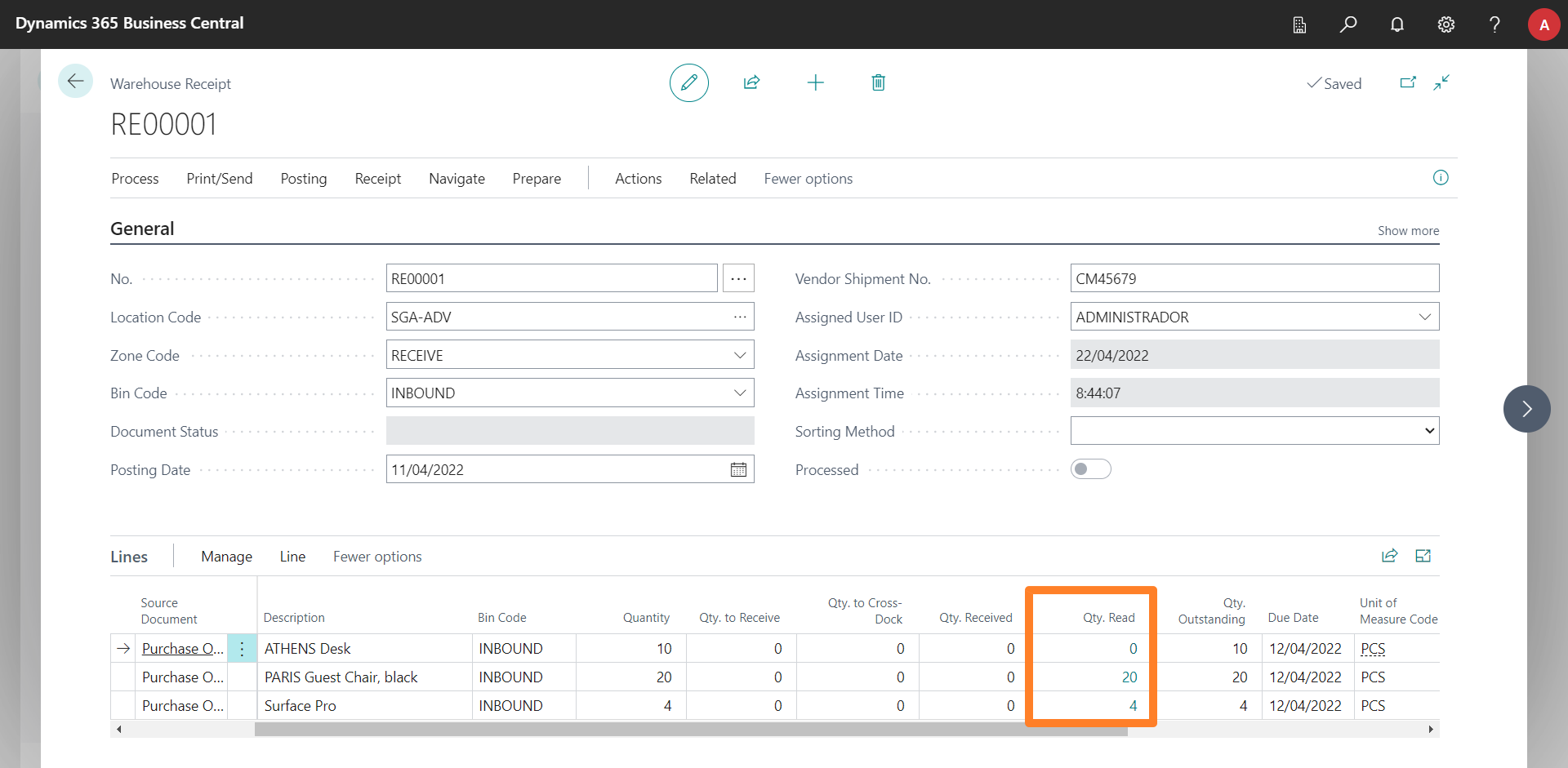

Quantity Read

A new field called Qty. Read is added to the warehouse document lines. It shows the quantity processed from the mobile application, and by clicking on the value you can see the detail of the readings sent by the user for the line.

When the document is posted, either from the mobile application or from Business Central itself, the value of this field will be copied to the Qty to Receive/Handle/Ship field (depending on the document).

Once any readings have been received for a line from the mobile application, the quantity to handle for the line will no longer be editable, as the quantity specified by the warehouse employee will take precedence.

Line Order

The mobile app lets user sort lines based on different criteria. By default, lines will be shown in the order defined by the Sorting Sequence No. field first, and the Line No. field second.

This means that, by default, users will see document lines in the same order as they are shown in Business Central. However, by customizing the value assigned to the Sorting Sequence No. field, customers could define any custom sorting that they might consider appropriate.

Extra Information

All lines that can be downloaded to the mobile app include a field called IDPWHS Extra Info, which can be customized to send extra details (color, material, manufacturer, notes, etc.) about the line to the mobile app. All info added to this field will be displayed to users on the screen, below the item name.

In the Developers section of this manual, you will find more information on how to customize the app.

Processed Documents

If the Automatic Post option is enabled in the warehouse employee setup, users will be able to post documents when finishing with them. If this option is not enabled, however, when employees are finished with a document, the Processed check box, available in all warehouse document headers, will be checked.

Once processed, these documents can then be reviewed by a warehouse employee for a final check-in.

Particularities by Document

Receipts

Receipts lines have an additional field: Qty. in Delivery Note, hidden by default. If any document line has this field filled in, the mobile app will show this value, instead of the outstanding quantity, as the maximum/expected quantity for the line.

The idea is that, in the case of partial receipts, the warehouse managers can fill this field with the vendor's delivery note data. This allows errors to be detected in the event that the quantity received does not match the quantity expected, even if the quantity outstanding was actually greater.

In the case of working with tracked items, the mobile application allows to specify the lots and/or serial numbers received. In this case, at the time of the document post, iDynamics Warehouse will update the tracking lines of each receipt line with the data obtained from the mobile application.

Warehouse Put-aways

Depending on what has been configured for the location, users will only handle place lines or both take and place lines. If it is the former, at the time of the post the application will not only apply the Qty. Read to the Qty. to Handle field, but it will also look for its equivalent line to take and apply the corresponding quantity read as well.

The bins assigned from Business Central are treated as a recommendation only. For practical purposes, the user will be able to place the item in a different bin, or even split it into several.

In case the item has configured in its card a storage unit different from the base unit of measure, the application will allow you to switch between both by clicking on the unit code in the quantities panel. This will allow you to indicate the quantity in any of the two units of measure.

Inventory Put-aways

Identical to warehouse put-aways, but for basic warehouses. Since in this case there is no previous receipt, there are no take and place lines: there will only be the option of specifying the bin where the items are placed.

As in receipts, the user can assign the lot or serial numbers that are received, if they were not pre-assigned from Business Central.

Warehouse Picks

Similar to warehouse put-aways, the mobile application users will be able to indicate the quantities/items selected in the lines to be taken or placed, or only in the lines to be taken, depending on what is configured at the location level.

In the case of handling items with tracking (lot and/or serial number), the user's freedom of action will depend on the values assigned to the lines: if the pick lines have a lot or serial number already assigned to them, it will be mandatory to take the specified lots or series from the location. If, on the other hand, the pick lines are generated without tracking, the mobile application will allow the user to select any lot or serial number from the assigned items.

The bins assigned from Business Central will be treated as a recommendation only. For practical purposes, the user will be able to take the item from a different bin or even complete a line by taking units from multiple bins.

As with warehouse put-aways, the user can indicate quantities in the base unit of measure or storage unit, if different.

Inventory Picks

Identical to warehouse pick, but, as with inventory put-aways, in this case, there is only one line per item on which to indicate the quantity taken from each bin.

Shipments

Users will not be able to handle shipments that currently have an assigned pick document. In addition, only released documents will be shown in the mobile app.

Warehouse and Inventory Movements

The operation is similar to that of ad hoc movements, in the sense that it will be necessary to scan the quantities that are taken and the quantities that are placed, with the difference that in this case the items and quantities are already given. The bins will also come pre-assigned, although the user will be able to modify them according to what has been configured in his employee card.